Would you like your own brewery too?

Make your dream come true!

Ringmaster will build a turnkey brewery for you

What you bring is a place with power and sewer connection. And of course a good dose of dedication, experimental skills and recipe ideas so that you can become the famous beer master of the area.

Magic in the brew

Ringmaster will invent your brewery style and help you create your beers.

Practical and safe

It requires minimal space. It can be expanded and even moved.

How is beer made?

1. Brewing and hopping

You can brew 650 litres of first wort in our three-kettle system at a time. We mash the prepared malt on the hot side of the brewery, then filtering follows. This consists of two phases: 1. we filter the hopped wort, and 2. we perform the sparging of spent grains left over from filtration. The result of the two filtering phases is sweet wort, which goes to the 3. kettle, that is, the brew kettle, where the soul of the beer, the magic hop gets in the hot potion, enriching the brew with aroma and bitterness.

2. Fermentation

At the end of the nearly 4-hour process, the beer goes through the heat exchanger and rests at a temperature of about 20 degrees Centigrade. There is nothing left to do but add yeast and prepare for the long fermentation. The chilled wort does not contain alcohol yet and goes to a fermentation tank where yeast is added. During its one-week primary fermentation, the sugars in the wort are transformed into alcohol and carbon dioxide with the effective help of yeast. Depending on the technology selected, fermentation may take place at lower (11-13 C) or higher temperature, providing bottom-fermented or top-fermented beers.

3. Conditioning

After the primary fermentation (about a week), second fermentation is started at very low (3 C) temperature. This is already the fermentation of the beer. We may also dry hop it to create additional scent and harmonious taste experiences. The finished beer is kept at an appropriate pressure and temperature, which are provided by the cooling jacket around the tanks. We can create different beers for each container using a temperature, fermentation time and various hops required for the specific beer.

4. Packaging

At the end of the process, the yeast is removed and we prepare for packaging in kegs or tanks. Brewing with Ringmaster comes with a taphouse concept: the fresh, ready-made beer can be tasted immediately from the taps of your own pub next to the brewery.

How can you get your own brewery?

Imagine what your brewery would look like.

Ringmaster will make it come true.

Tell us where to install it.

All you have to do is brew!

Let’s see the magic of brewing!

Ringmaster has created his own brewery.

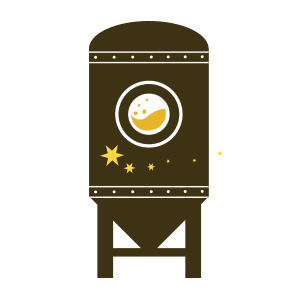

A well-calculated, customizable brewery has been born. The brewing cauldrons and fermentation tanks nicely fit in 2 marine containers. The brewery has also created its first beer. A brand new lager is coming soon!

Dreaming of your own beer? Would you like to be an independent brewer too? Make your dream come true and get a mobile brewery of your own with the help of Ringmaster!

Technical parameters

Sizes (the basic design includes 2 pieces of 20-foot sea storage containers):

length 6058 mm x width 4876 mm x height 2900 mm

Weight: cca.10,000 kgs

Base ground surface: 6-point pile foundation or monolithic concrete (flat)

Required connection of utilities:

-

Electricity 80A (one-time maximal nominal electricity demand), 3x 400V, 50Hz

-

Water drinking water quality tested water intake. Filtering equipment and water softening equipment can be installed

-

Sewer the wastewater from brewing contains biodegradable substances only, therefore it can be drained directly to sewer utilities

-

Insulation the wall of the container is made of 6 cm thick PUR sandwich panel, which, according to its thermal insulation capacity, corresponds to a frame ceramic wall with a cross section of 30 cms

-

Hygiene: CIP mobile washing equipment is available for the cleaning of KEG barrels, kettles and tanks.

Brewery variations

Due to the excellent buildability of standard containers, the design of the brewery can be imagined as a lego game: put the tap house on the ground floor and the brewery upstairs. Why not? Ringmaster’s brewery offers a modular design and expandability: if the company has produced the cost of capacity enhancement, build another fermentation module on top of, added to, behind or possibly in front of it. Or just put a lookout terrace on top… All variable. You may also repaint it to decorate the walls of the container – your appearance may be different each year.

Contact us

Copyright © 2020 Porondmester

All rights reserved.

Powered by Activium

SI-KER’993 Betéti Társaság

Hungary, H-1039 Budapest, Ady Endre utca 4.

E-mail: info@porond-mester.hu

Phone: +36 20 943 9748